Control Module

The Control module is used to perform simple tests to see if an asset is either In Control (near the expected values) or Out Of Control (outside the expected values).

It is very similar to the Limit module, except for the fact that the Control module takes a single target and a span, while the Limit module takes an upper threshold and and lower threshold instead.

The analytic returns a list of time-frames, and the assets status (Under Control or Out Of Control) during those time-frames.

Starting Out

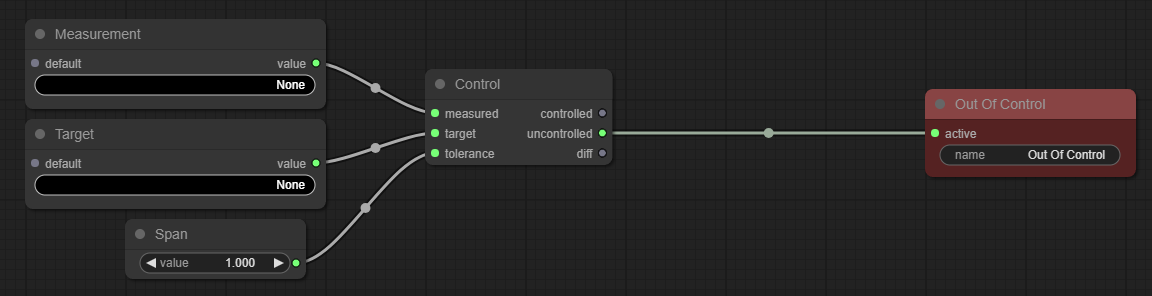

When you first create a new Control analytic, you'll see the graph below…

The node in the middle is the Control node, which takes the measured, target and tolerance values and determines if the current inputs look like they are close to target.

The tolerance value is the amount the actual value is allowed to drift from the target. For example, if there was a target of 20 and a tolerance of 2, a value of 24 would be considered uncontrolled because it's more than 2 units away from the target.

On the right is the Control Output node - if the value going into this is true, the analytic considers you out of control. If it's false, you're in control.

Why Two Nodes?

There are a number of reasons why control can deliberately drift outside the expected range, such as when the system is shut down, running manually, or in the middle of preparing for a new or different batch of product.

The gap between the 'control' node and the 'Out Of Control' node is where you can add any of this additional logic.

You can also add Timers to your graph if you want to delay things. Ensuring that it stays out of control for more than 5 seconds can help deal with sudden spikes, inrushes or sensor issues.