OEE Example: Simple OEE Calculation

In this example, we will calculate a rough Overall Equipment Effectiveness for one of our machines - Bridle #1.

This will help point out where machines are either being under-utilised or failures are impacting on production and/or quality.

Complexity

Because OEE is more complex than some other metrics, this tutorial isn't quite as step-by-step as the previous examples. It's assumed that you know how to add a node and are familiar with some of the basic node types.

If you're new to the visual analytic system, we suggest looking at the tutorials for simpler modules, such as Control or Pivots.

Available Information

| Asset | Property | Desc |

|---|---|---|

| Paint Line | Status - Painting | Has a value of 1 when painting, and 0 when stopped. |

| Paint Line | Speed - Actual | The speed the machine is running |

| Paint Line | Current - Field | The amount of power being used by Roller #2 on the machine |

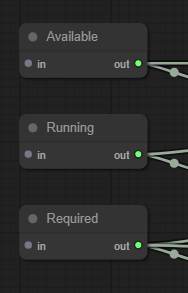

Initial Layout

The key nodes are the three on the far-left. We need to provide logic for how the system can tell that the asset is…

- Available (should be able to run if requested),

- Running (actually running), and

- Required (needed to run)

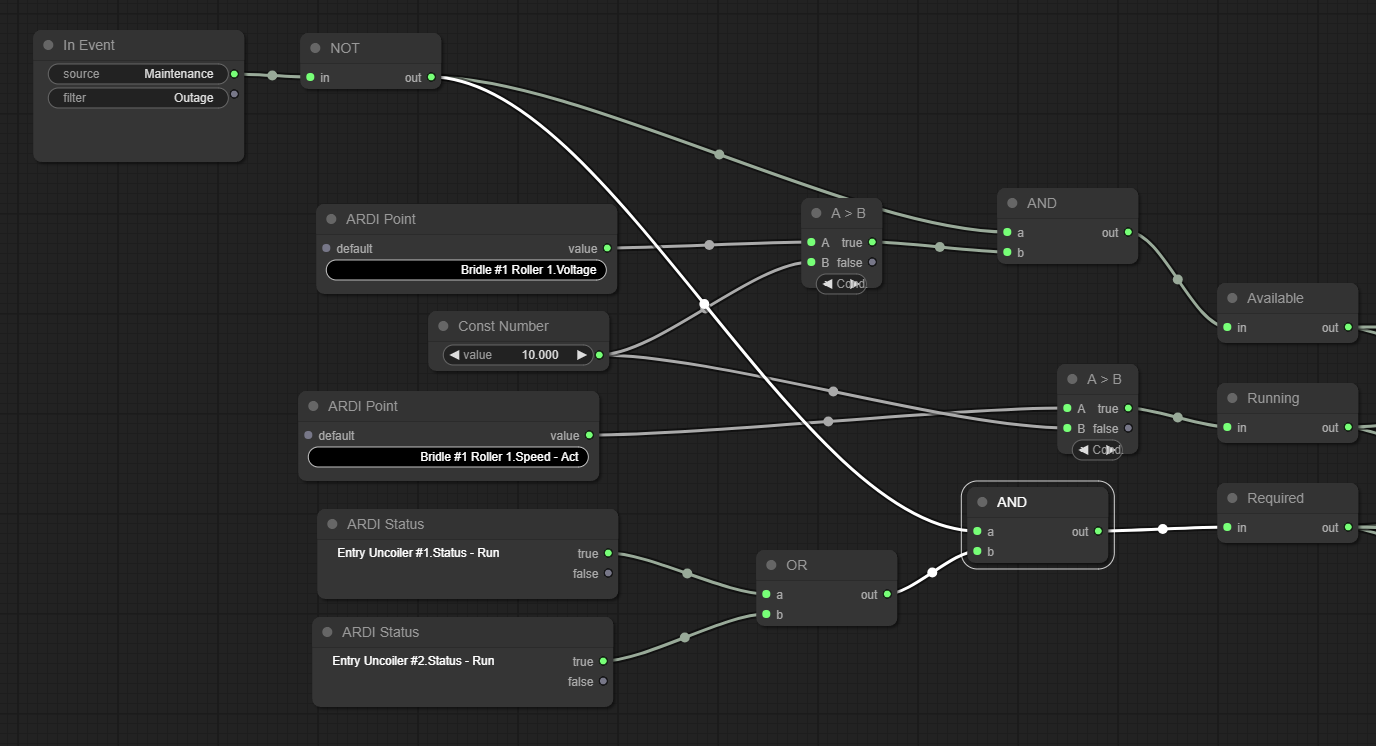

Step 1: Available

The first step is to choose the rule we will use to tell if the machine is available. This isn't always trivial, but you can often find a combination of points that provide the detail we need.

In this case, we'll use voltage to tell if the machine is available. Since it should be ready to run whenever it's powered, this should be a good guide that the machine is available.

You could also consider using automation status (ie. auto, manual, bypass etc.) if available.

In this case, we've added a ARDI Point for the asset voltage, a Constant Number for the minimum value, and a Condition node to determine that the voltage is greater than 10V.

Step 2: Running

We can do something quite similar for running - the machine has speed sensor we can use to see if it's actually doing its job.

So we'll use the same logic - if it's moving at more than 10m/min, we should count consider the machine running.

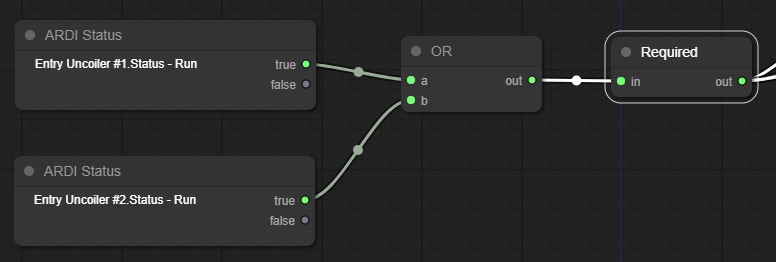

Step 3: Required

Of all of the parts this analytic needs, required is the most complex, as it normally involves logic from other assets.

In this case, Bridle #1 pulls the product out of two different machines - Entry Uncoiler #1 and Entry Uncoiler #2.

If either of these machines are running, we're required.

Luckily, these assets have simple I/O points for if they're running or not. So this gives us….

Analytic Complete

And we're done - by pressing Save and Visualise, we can access a simple display of the OEE over the last

Further Refinement

Right now, we don't do any compensation for outages that are beyond the control of the machine or the people who run it.

If we had a scheduled outage to replace a motor, the OEE would drop severely - which we don't really want if we're need to have that outage for the good of the equipment.

You can add additional logic to Available and Required to cater for other factors.

For example…

This logic checks to see if there are any 'Outage' events on the maintenance calendar at the moment - if so, the machine is considered both unavailable and not required.

You could also tackle this further down-stream, by adding a new machine condition.