Shear Tracking Module

The Shear Tracking module is targeted specifically at longwall mining applications, where it is used to monitor the movement of the shearer and convert that into a list of cutting passes, known as shears.

Starting Out

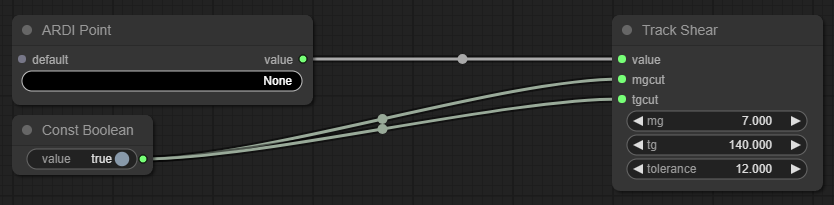

When you first create a new Shear Tracking analytic, you'll see the graph below…

The node on the right is the Tracking node.

It needs to be set up to match your wall. There are a few key steps involved.

Note that the three parameters of the Tracking node are specified in terms of roof supports.

- Set the mg option to a small number of supports in from the support #1 (the Maingate). We usually suggest 6 or 7.

- Set the tg property to the same at the Tailgate end. For example, in a 155-support-wide longwall, we'd suggest using 148.

- Set the tolerance to be equal to the largest expected distance from either the TG or MG during a double-cut.

Once that's set up, you need to provide inputs.

- Set the value to the current shearer position, in roof supports. If you only have shearer odometry instead of support number. you can usually use a Division node.

- Set mgcut and tgcut to appropriate values if you're shearing in that direction. For example, if you cut bi-directionally, both should be true. If you're cutting uni-di from maingate to tailgate, tgcut should be true and mgcut should be false.

Module-Specific Nodes

Output

The output of the module is a single shear event for every shearer pass.

The shear information includes…

| Property | Description |

|---|---|

| ID Number | A unique ID number for the shear |

| Start | Start Time |

| End | End Time |

| Duration | Total seconds of duration |

| Direction | The cut direction (MG to TG or TG to MG) |

| Mode | The cutting mode of the shearer (BIDI, MG-TG, TG-MG, TRAVERSAL) |

| Cutting | 1 if this is a cutting pass, 0 if it's a traversal pass |

| Complete | 1 if the shear is complete, 0 if it's incomplete |

Double Cuts

By default, the last entry into the gate-end is treated as the start of the next shear. This means that if your shears include a double-cut, they'll always be at the end of the shear rather than at the start.